Making the best use of cardboard boxes, plastic bags and packaging is at the heart of the HESSERBraC ethos under which ÏDKIDS is committed to reducing the impact of its products on the environment.

Two types of packaging get our attention:

1. PRIMARY OR PRODUCT PACKAGING is the immediate layer of packaging users see and touch when they buy the product. Protection and branding are its main functions.

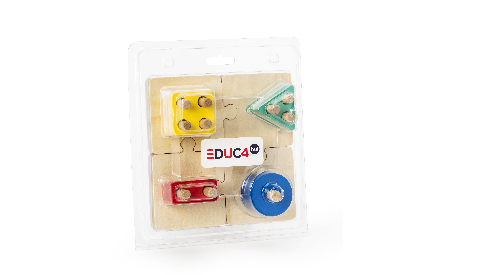

Oxybul has focused on two aspects of primary packaging:

- Eco-designing new products to make the best (i.e. least) use of packaging, like this ball whose label is printed directly on rather than attached to it.

- Refitting existing packaging so that there is only one piece of packaging to dispose of, boxes have no “empty” spaces and recycled materials are used wherever possible (32 items have already been repackaged in this way). Video hereafter

Before :

After :

2. SECONDARY OR TRANSIT PACKAGING allows the product to be transported safely from the warehouse to the store or directly to the customer.

Since June 2018 Okaïdi has worked on finding ways to get rid of the plastic sleeves in which individual items are packed and on which barcodes are stamped in the boxes used to ship every new collection. Since September 2018 it has achieved this for three-quarters of its product families. This means that 8,842,186 items have been ordered without plastic sleeves, which equates to 44 less tonnes of plastic. The next step is to reduce the number of plastic sleeves in boxes used to ship fresh stock.

8,842,186 items ordered without plastic sleeves,

which equates to 44 less tonnes of plastic in 2018

In addition, new packaging machines have been installed at Okaïdi’s logistics facilities. These machines fold boxes according to their contents, making them exactly the right size. This has increased the number of boxes that can be stacked on a pallet from 20 to 40 and thus reduced the number of trucks needed to transport them. A new automatic carton sealer has also allowed us to make our boxes more secure while making life easier for our packers.

We’re thinking outside the box, one flap at a time. More to come in our bag of tricks!

Video : Diana Amorim, Oxybul Packaging Engineer, explains how it works :